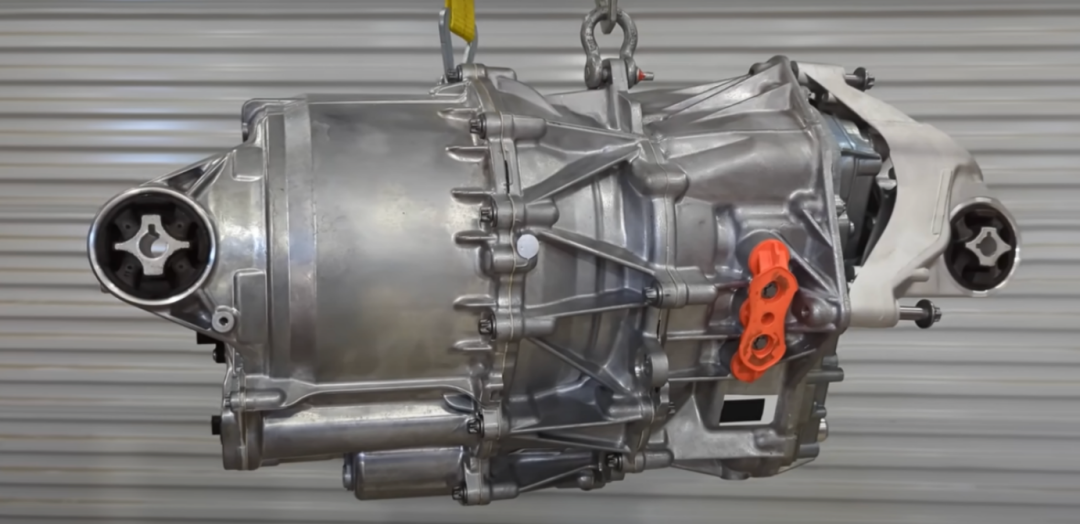

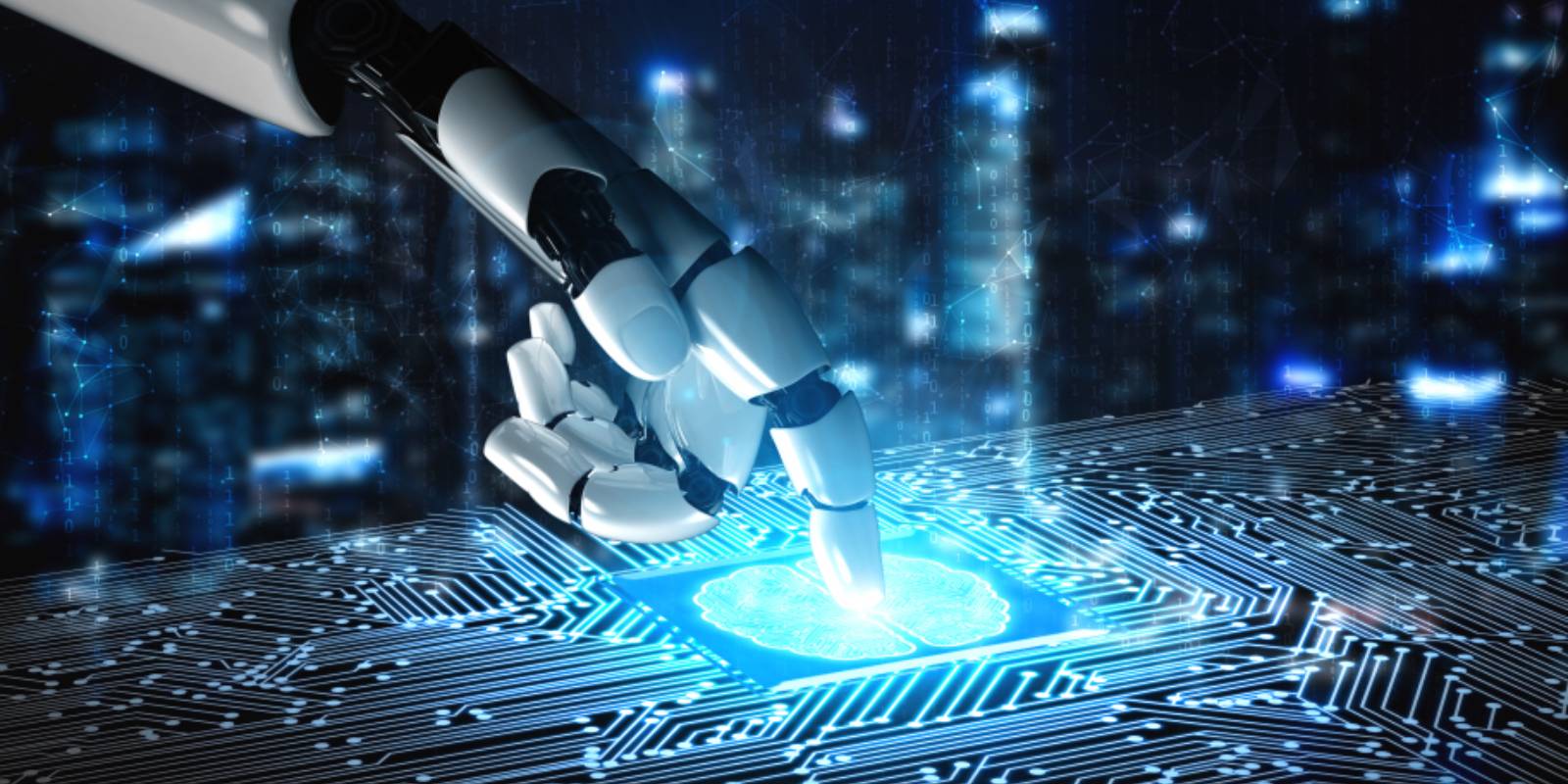

We are excited to share an in-depth teardown and analysis of Tesla's 4th generation drive unit (DU). This latest DU is believed to originate from Tesla's Texas Gigafactory and is currently used in the rear drive of the Model Y, while also being compatible with the rear position of the Model 3.

This new generation is an evolution of the 2017 Model 3 rear-drive PM SRM drive unit, retaining the strengths of its predecessor while introducing numerous optimizations in design, manufacturing, and performance.

1. Overall Structure and Layout

The overall layout of the 4th generation drive unit remains consistent with previous versions but has been fully optimized in detail. Its main components include:

* Inverter

* Cooling system

* Oil pump and heat exchanger

* Gearbox

* Electric motor (stator and rotor)

The positions of these components follow Tesla's traditional design philosophy, but structural connections and materials have been innovatively improved.

Key Advantages: Compact layout, optimized connections, and lightweight design.

2. Key Component Analysis

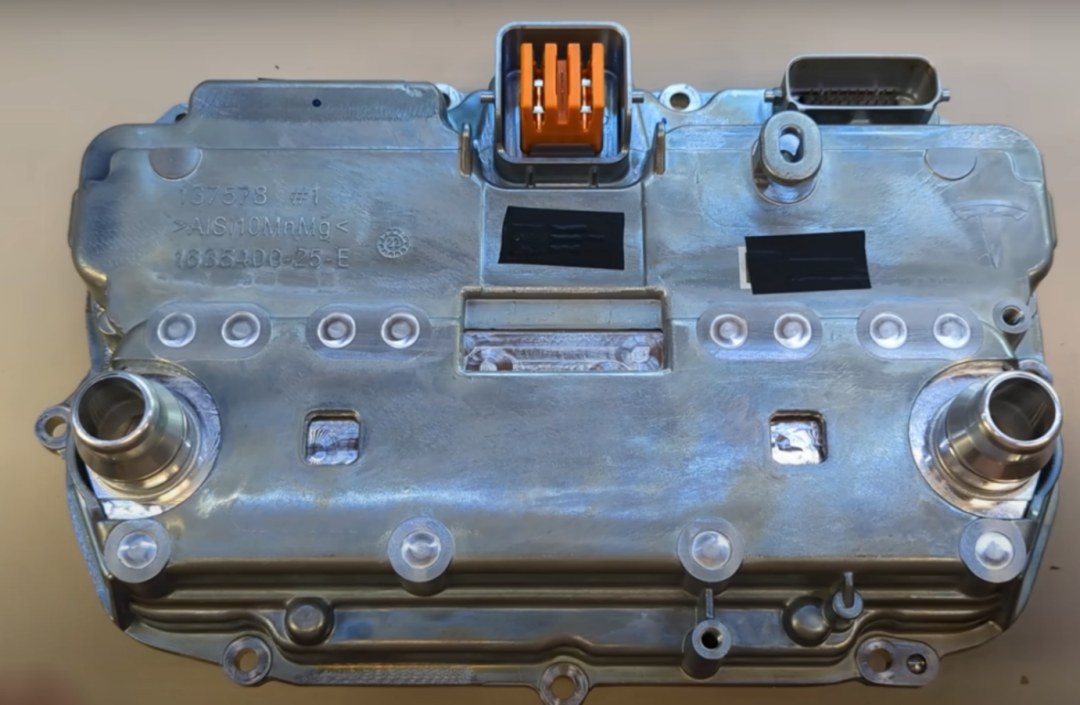

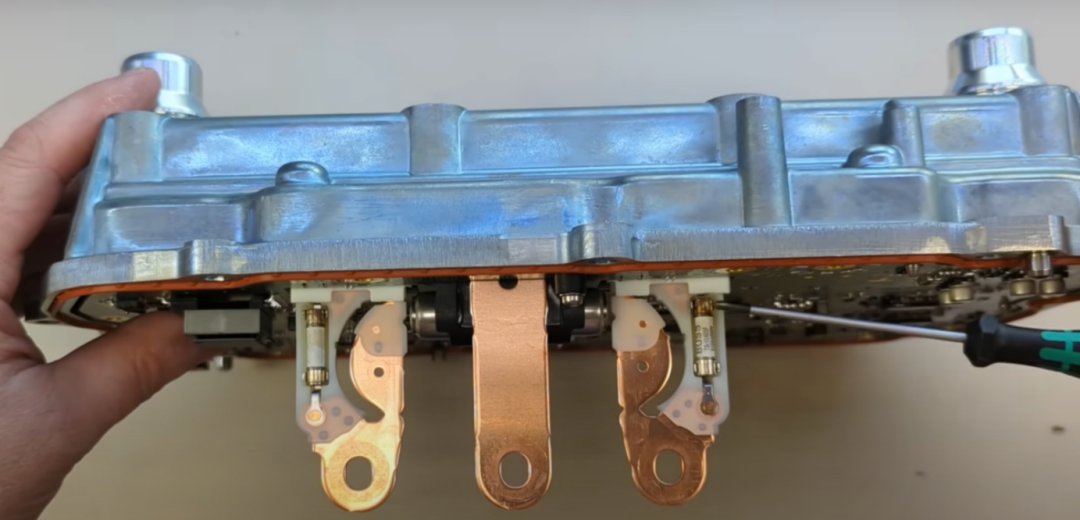

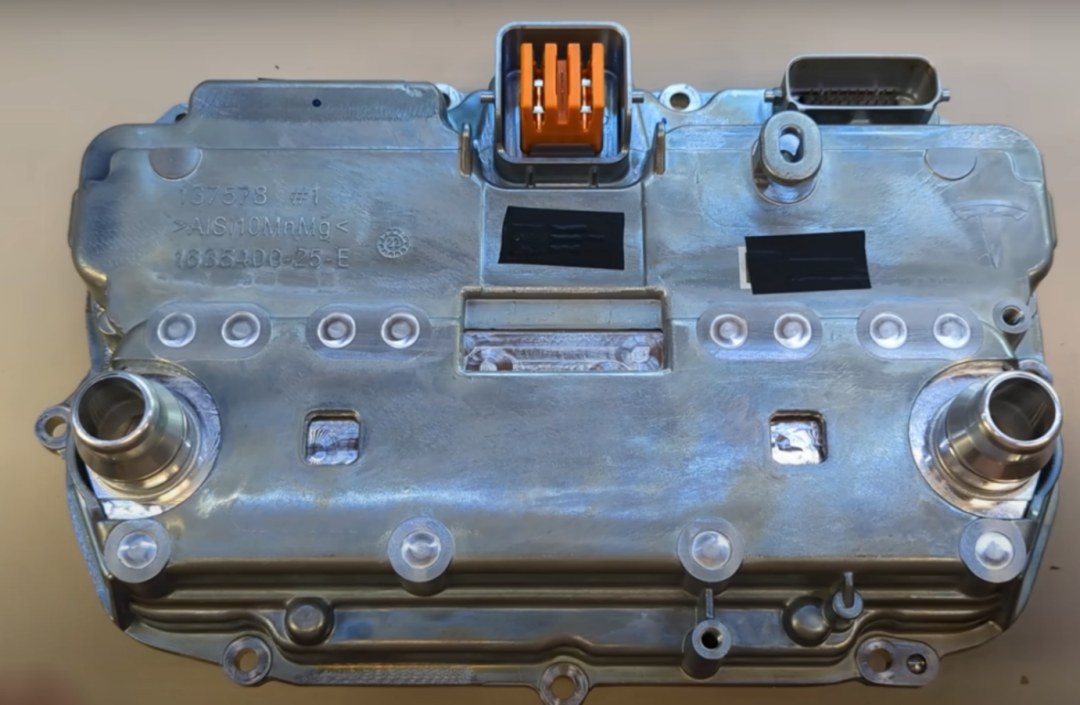

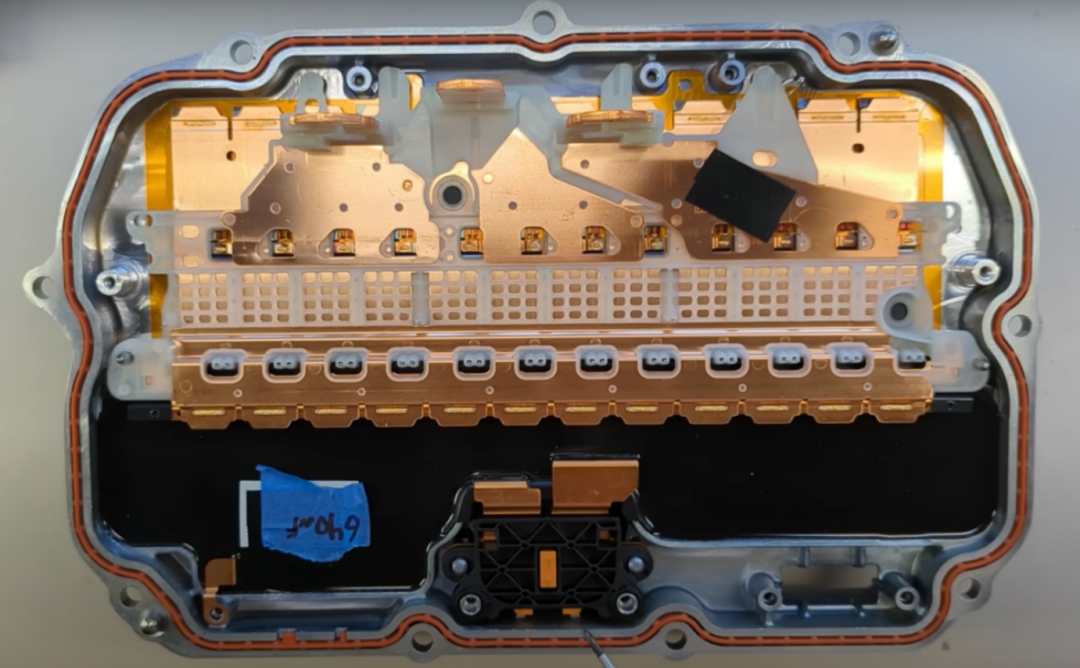

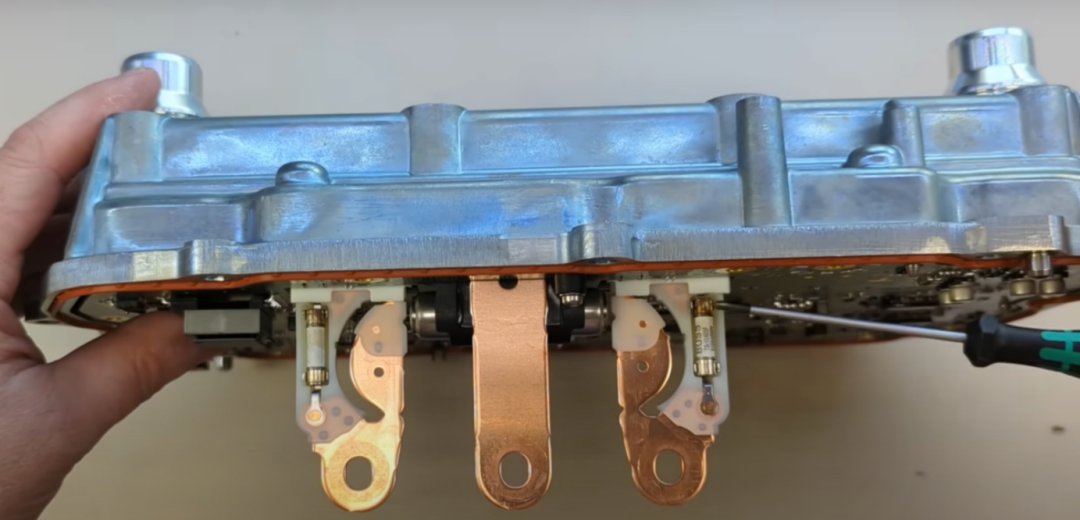

2.1 Inverter

* Redesigned as a compact rectangular shape with integrated casting.

* High-voltage and data connectors are molded in place.

* Integrated new cooling module connected via friction stir welding, optimizing material usage and fasteners.

2.2 Electric Motor

* Rear vent assembly retained, but positioned higher to form a shield against water ingress.

* Fewer ribs on the casting, contributing to a lighter structure.

* Rotor design similar to previous generation; stator uses a new hairpin design:

* Higher winding fill ratio

* Automated manufacturing process, eliminating hand-wound copper wires

* Significant reduction in production cost

* Internal components include:

* Stacked plate heat exchanger for gear oil cooling

* Permanent cylindrical oil filter, integrated into the housing and maintenance-free, designed to trap micro debris throughout vehicle lifetime

Innovations: Hairpin stator, optimized thermal management, maintenance-free oil filter.

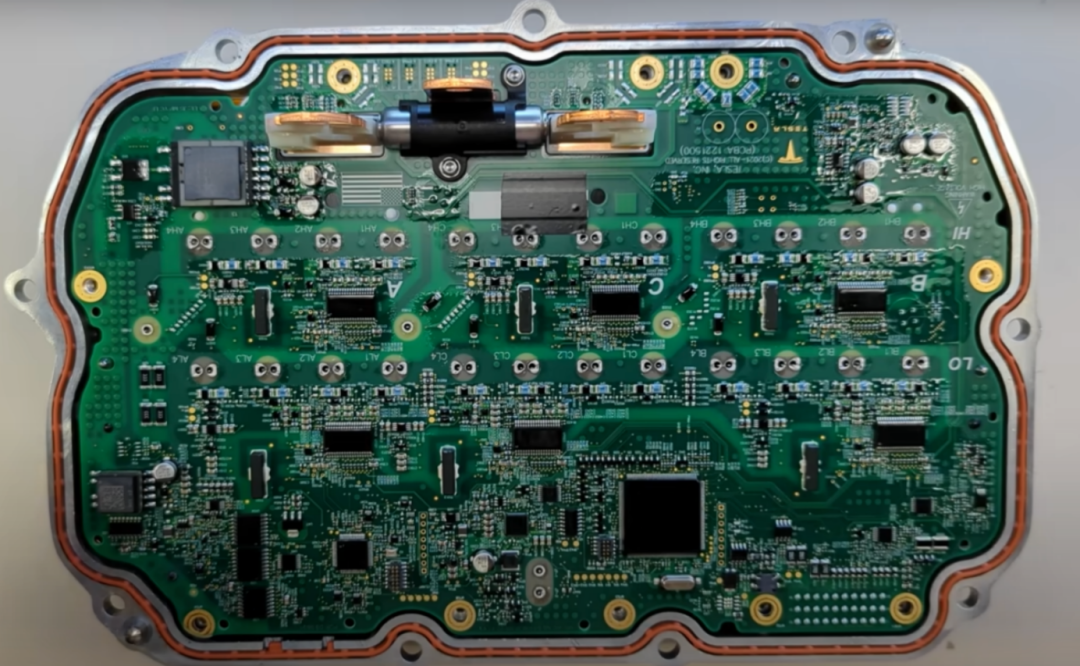

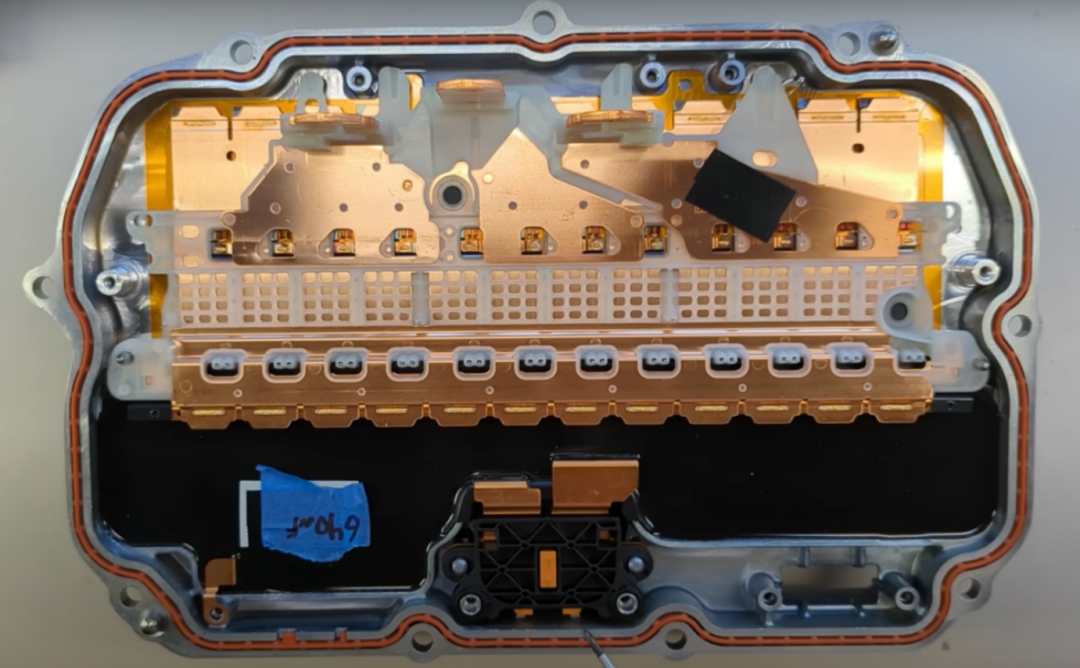

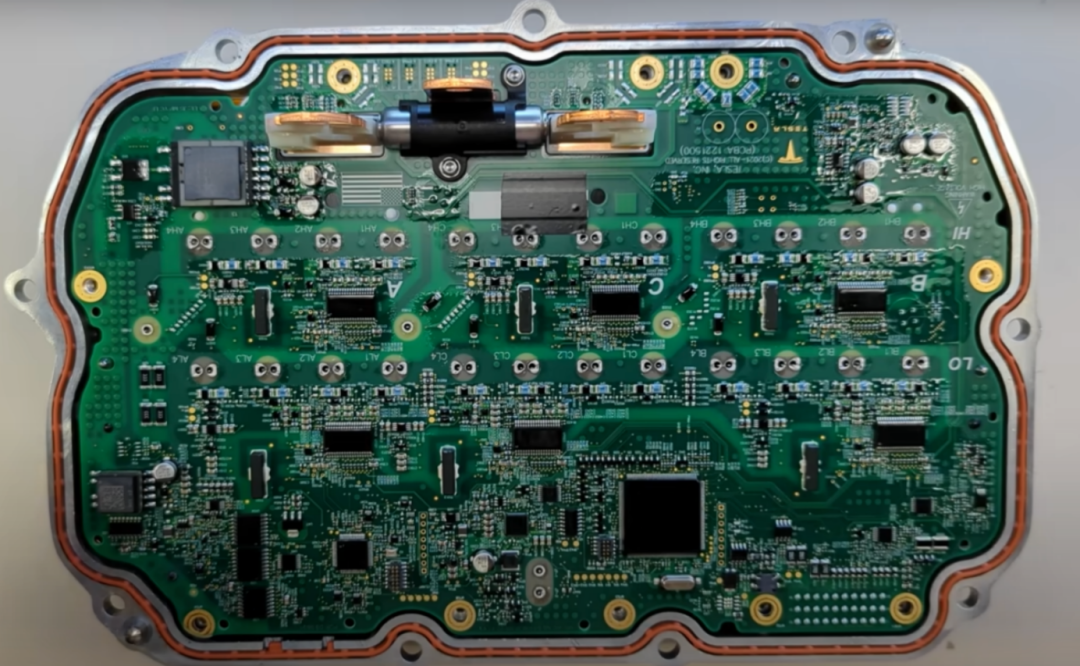

3. Inverter PCB and Safety Features

* PCB design is more compact, with advanced safety mechanisms:

* Pyroelectric disconnect for rapid two-phase motor cutoff during faults

* 10,000A interrupt fuse works in tandem to safely cut current and extinguish arcs

* Core control chip: TI TMS320 dual-core DSP

* Added custom safety controller

* Current sensors measure two phases, with the third phase calculated by difference

* Temperature monitoring upgraded to non-contact infrared sensors, replacing traditional thermistors

* Discharge resistors removed, likely handled via motor windings or MOSFETs

* Power section uses planar PCB transformers, providing isolated power for each gate driver at low cost

Key PCB Components

| Function | Model / Vendor |

|---|

| Main DSP | TI TMS320F28377DPTPQ |

| Safety Controller | Tesla proprietary 16324 1TC TC14427 2212 |

| Gate Drivers | ST STGAP4S |

| IR Temperature Sensors | ACC T5977510 |

| Digital Isolators | TI ISO7741FQ / ISO7762FQ |

| Analog Isolator | TI AMC3330-Q1 |

| Pyro Bypass Fuse | Buss TS-10A05F T10AH500V |

4. Summary

Tesla's 4th generation drive unit represents a significant evolution over its predecessor:

* More compact design

* Lower manufacturing costs

* Improved performance and reliability

* Innovative technologies: Hairpin stator, optimized cooling connections, and advanced temperature sensing

These innovations showcase Tesla's ongoing exploration and advancement in electric drive technology, reflecting a mature and efficient approach to EV powertrain design.

AXTEK Solutions for Your EV Projects

At AXTEK Electronic Co., Limited, we offer:

* Large stocks of TI DSPs and related components

* Long-term procurement channels for consistent supply

* Expert technical support for EV and power electronics projects

Contact us today to secure inventory or discuss long-term orders for your EV solutions.

MCU Solutions

MCU Solutions PCBA Solutions

PCBA Solutions Bluetooth Solutions

Bluetooth Solutions

FAQ

FAQ Contact Us

Contact Us

Company News

Company News Technology News

Technology News Industry News

Industry News PCBA News

PCBA News

Company Profile

Company Profile Certificates

Certificates Terms & Conditions

Terms & Conditions Privacy Statement

Privacy Statement

Home Appliances

Home Appliances Beauty Appliances

Beauty Appliances Lighting

Lighting Kid's Toys

Kid's Toys Security Alarm

Security Alarm Health Care

Health Care

More information?

More information?